Office Buildings

According to the U.S. Environmental Protection Agency, we spend over 90% of our time indoors.

According to the U.S. Environmental Protection Agency, we spend over 90% of our time indoors.

IAQ Trends for COVID Reentry

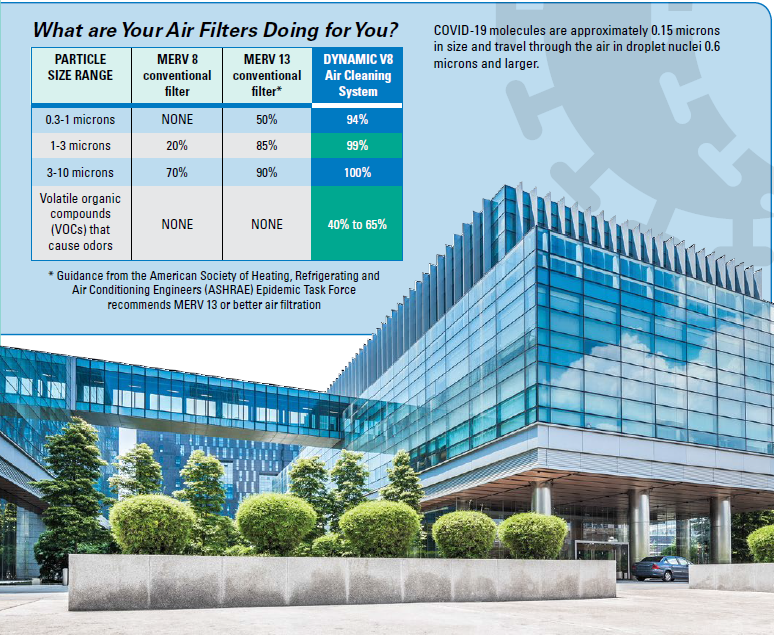

The COVID-19 pandemic has placed a lot of emphasis on indoor air quality. With respect to HVAC systems, experts have stressed increasing outdoor ventilation air, MERV 13 or better air filtration, and use of portable air cleaners and germicidal UVC lights. Indoor Air Quality (IAQ) is a complex issue. It’s a long-standing issue that has roots in many other problems. The size, type and age of buildings, climate, and the vast array of mechanical systems are just part of the issue.

As we start to see some light at the end of the tunnel regarding the pandemic, it’s a good time to think about an effective long term air quality strategy for your facilities. A sound IAQ strategy can not only help keep occupants safe, improve cognitive functions, and reduce absenteeism, but it can also provide a path toward sustainability, lower operating costs, and a more environmentally friendly footprint.

To make informed decisions about IAQ, it’s important to understand some of the basic tenants.

The Most Common IAQ Problems

Airborne contaminants indoors either originate within the building or are drawn in from the outdoors. If pollutant sources are not controlled, indoor air problems can develop, even if the HVAC system is properly designed, operated, and maintained. Sources of indoor air contamination include underground sources (e.g., radon, pesticides, leakage from underground storage tanks), and a variety of indoor sources (e.g., equipment, furnishings, and cleaning supplies). Concentration levels of air pollutants can vary greatly by time and location within a building, or possibly a single room. Pollutants can be emitted from point sources, such as kitchen facilities, or from area sources, such as newly painted surfaces. And pollutants can vary with time, such as only when floor stripping is done.

IAQ problems that generally get the most attention are those that involve lots of complaints. Issues can be exacerbated by allergic reactions and health issues. These often involve outdoor contaminants that are being entrained into the building with outdoor ventilation air. One of the most common issues involves vehicle emissions. Vehicle exhaust can be problematic when the building is located in an urban setting or near heavily traveled roads.

Outside ventilation air is used to dilute airborne contaminants but outdoor air can also be more problematic than indoor air, especially in urban areas. With today’s low-VOC emitting building materials, furniture, and cleaning chemicals, and with the absence of indoor smoking, airborne particle and odor contaminants are much more apt to enter a building through the fresh air intakes. To cope with these issues, designers and facility managers have found that air cleaning systems can be incorporated into the HVAC systems to not only clean the incoming fresh air, but also to keep indoor air at contaminant levels below outdoor levels.

Cost Savings

Even though good IAQ has real, tangible benefits, it is still largely cost driven. So where are potential savings for facilities that implement these applications?

Energy costs present the largest opportunity. HVAC accounts for about 40 percent of the energy used in U.S. commercial buildings, making HVAC fan energy a good target for cost reductions and savings on a facility's annual operating budget. In new buildings, according to the U.S. Department of Energy, adopting energy-efficient design and technologies – in HVAC and other areas – can cut energy costs by as much as 50 percent. And in existing buildings, renovations that replace older systems with more efficient technology can yield savings of up to 30 percent. With respect to only IAQ and the air filtration component of an HVAC system, significant operational savings can be found through:

- Reduced fan horsepower from lower static pressure

- Reduced ventilation air requirements

- Reduced maintenance and disposal costs from longer service intervals

Addressing air filtration alone can reduce a buildings total energy footprint by five to ten percent. Historically, increasing filter efficiency has meant increasing energy and operating costs because it takes more fan horsepower to push air through denser, more efficient filter media. The denser the filter media, the higher the static pressure resistance. With a lower static pressure, less fan energy is required to move air through the HVAC system. Lower static pressure corresponds directly to energy savings.

Dynamic polarized-media air cleaners offer relatively low resistance. In some cases, there can be mid-life pressure drop savings of up to one and half inches versus passive, mechanical filters. This allows fans to be designed and selected with lower horsepower requirements and potentially less operational energy consumption.

Maintenance costs present yet another area for savings and include labor, ordering, handling, storage, and filter disposal costs in addition to materials. High efficiency air cleaning systems such as the Dynamic V8 Air Cleaning System, offer very high dust-holding capacities and can extend change-out intervals from every several months to every several years.

Although cost controls may typically steer facility managers toward lower front-cost options, particularly as it relates to air filtration, sustainability initiatives are highlighting a broader goal. Increasingly, sustainability initiatives have been trumping cost initiatives. In some cases, a high efficiency filtration system can pay for itself in less than two years. As we’ve mentioned, fan horsepower and system static pressure greatly impact energy consumption. Filter replacement costs and length of maintenance intervals influence ongoing operational costs. These costs can be evaluated to determine the life cycle costs.

Over 90% of the cost of air filtration is energy,

Over 90% of the cost of air filtration is energy,

making it low hanging fruit for an energy conservation

measure – without sacrificing air quality

Good IAQ improves health, well-being, and performance. Develop an IAQ strategy that will enable you to improve IAQ while reducing energy consumption and lowering operating costs at the same time.

Net savings on using Dynamic Air Cleaners can often generate a return on investment of two to four years.

Case Studies

Class-A Urban Office Building

IAQ Challenge: Sustainable design, vehicle emissions, extended media life

Solution: Dynamic V8s

Union Fenosa Corporate Headquarters

Energy Challenge: Reduce HVAC Energy Consumption

Solution: Dynamic V-Banks

Lafarge Factory Offices

IAQ Challenge: Dust from limestone quarry

Solution: Dynamic V-Bank and V8 Air Cleaners